Crosslinked Shrink Film plays an important role within modern packaging environments where durability, surface quality, and controlled enclosure matter simultaneously. Crosslinked Shrink Film responds smoothly during heat exposure, forming a stable outer layer that follows product contours while maintaining visual balance. This behavior supports brands seeking packaging solutions that align appearance, handling confidence, and operational consistency without unnecessary complexity.

During application, gradual contraction allows materials to settle evenly around enclosed items. That controlled movement reduces surface stress while preserving shape alignment throughout handling stages. Unlike rigid wrapping methods, this approach maintains flexibility, allowing products to remain protected without sacrificing presentation clarity. Such balance proves valuable for operations managing varied item forms across diverse packaging workflows.

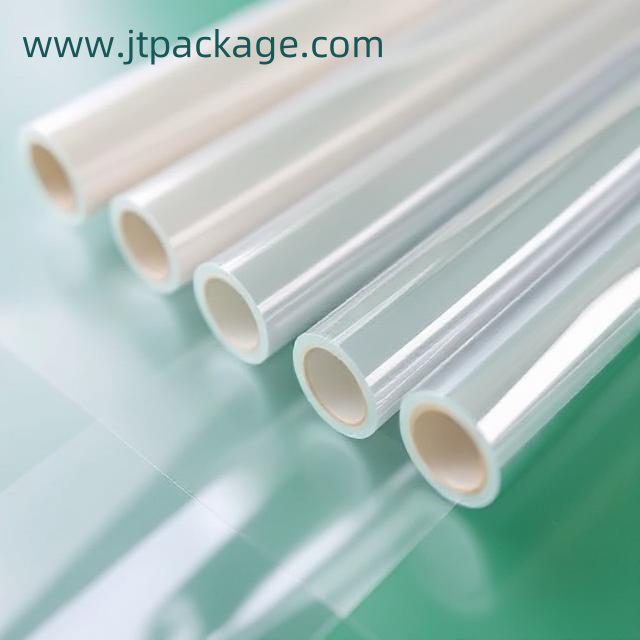

Visual performance remains a central consideration. Clear surfaces allow immediate recognition, supporting trust through visibility rather than excessive messaging. Smooth wrapping frames product identity naturally, letting colors, forms, and labeling remain prominent. This restraint strengthens perceived value by allowing packaging to complement branding rather than compete with it.

Operational efficiency also benefits from predictable material behavior. Consistent response reduces adjustment needs across packaging lines, supporting steady throughput and reduced disruption. Adaptable enclosure supports varied unit groupings using a unified approach, simplifying inventory planning while maintaining uniform presentation across different product categories.

Environmental responsibility continues influencing material selection. Lightweight structure supports efficient use while maintaining protective coverage. Recyclable characteristics align with evolving sustainability expectations without compromising surface appearance. Brands seeking balance between responsibility and refinement often favor solutions that quietly support both goals.

Protection during movement remains essential throughout distribution cycles. Secure enclosure minimizes friction and surface contact, reducing exposure during storage or transit. Items remain aligned and stable, supporting arrival conditions that reflect care and quality. Such reliability contributes directly to customer satisfaction and long term brand confidence.

Within branding strategies, subtle packaging often communicates strength. Clean surfaces enhance form definition while preserving visual harmony. Rather than drawing attention away from products, the film supports identity expression through clarity and restraint. This approach benefits premium positioning where simplicity reinforces trust.

Adaptability across usage scenarios adds further value. Varied shapes, grouped units, or individual items can be enclosed using consistent methods, reducing complexity across packaging operations. That flexibility supports scalable growth while preserving visual alignment across expanding product ranges.

Supplier reliability influences final results. Material consistency, responsive coordination, and aligned expectations help maintain quality across long term partnerships. Businesses selecting dependable partners often prioritize clarity, stability, and shared commitment to evolving packaging standards.

Within this landscape, JTPACKAGE represents a focused approach toward packaging solutions built around controlled performance, visual balance, and adaptable application. Additional insight regarding material behavior and usage considerations can be accessed through this reference https://www.jtpackage.com/news/industry-news/crosslinked-shrink-films-an-innovative-force-in-packaging.html